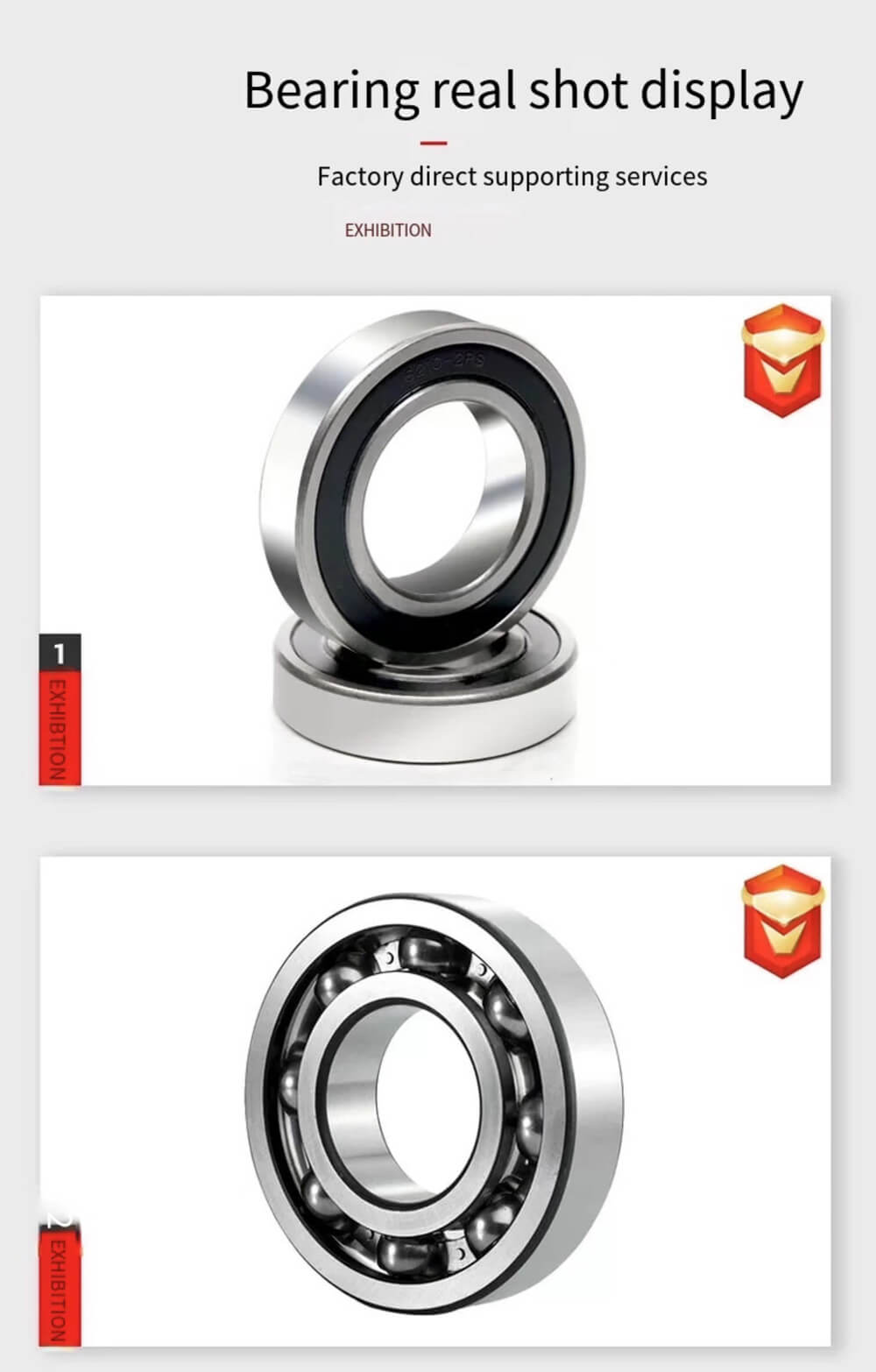

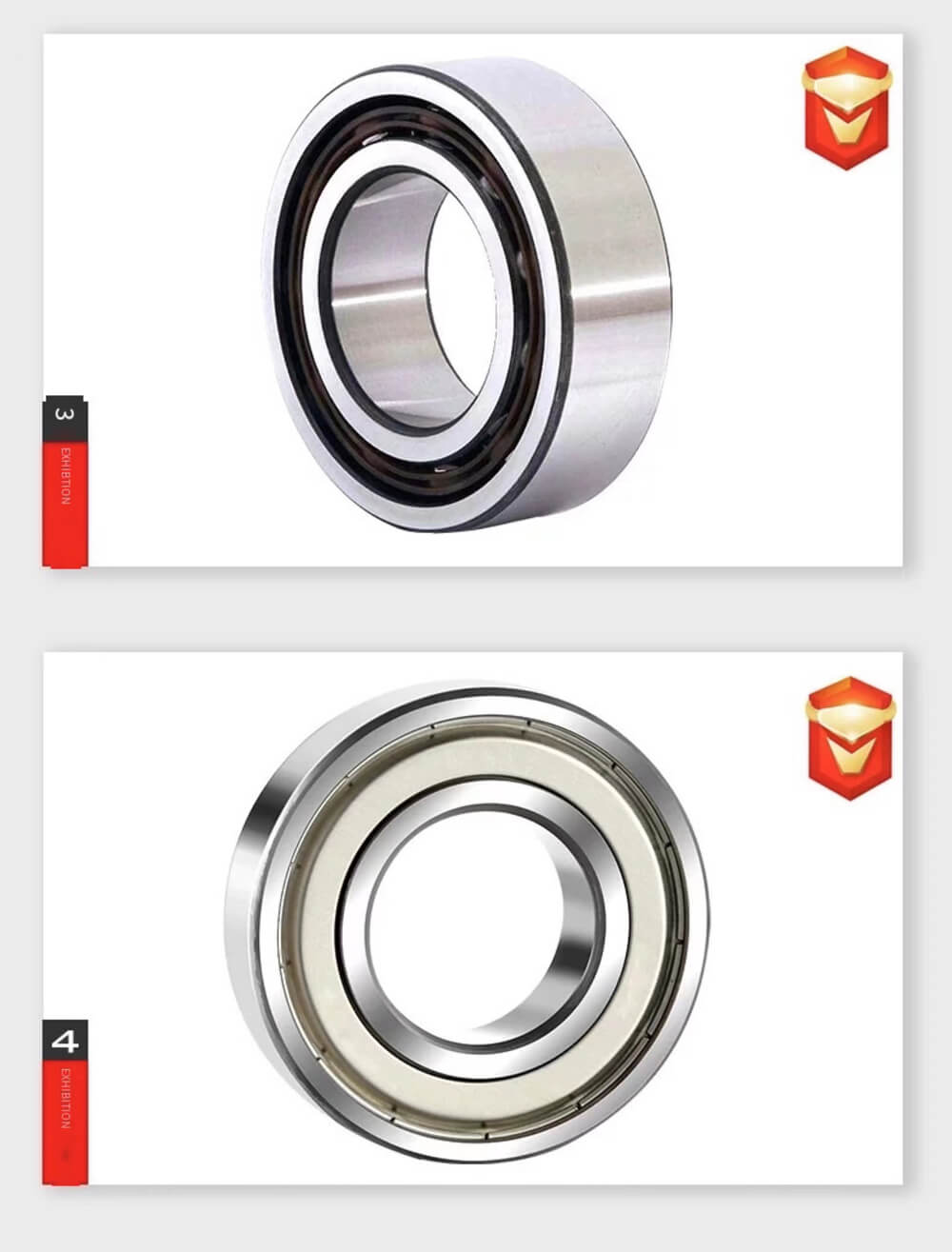

Deep trough - most commonly used. Suitable for high speed and low friction, noise and vibration. This type of bearing can withstand radial and axial loads in both directions. Angular contact - suitable for high precision, speed and axial loads in gearbox, pump and machine tool applications. Self-alignment - For applications where static and dynamic misalignment occurs. These bearings are ideal for high speed and light load applications. Thrust - can be used for unidirectional and bidirectional bearings. They are intended for axial loads only and should not be subjected to radial loads.

Deep trough - most commonly used. Suitable for high speed and low friction, noise and vibration. This type of bearing can withstand radial and axial loads in both directions. Angular contact - suitable for high precision, speed and axial loads in gearbox, pump and machine tool applications. Self-alignment - For applications where static and dynamic misalignment occurs. These bearings are ideal for high speed and light load applications. Thrust - can be used for unidirectional and bidirectional bearings. They are intended for axial loads only and should not be subjected to radial loads. Sealing cover material: galvanized iron cover/frosted iron cover/stainless steel cover/rubber cover. Ingenuity process Bainite quenching: the bainite quenching process is adopted, after quenching, the bearing molecules are closer and the service life is longer. CNC equipment automatic processing: the use of automatic CNC equipment processing and manufacturing, reduce the error and uncertainty of manual assembly. 1: smooth surface: bearing surface is smooth without burrs, smooth and convenient installation, surface polishing treatment. 2: No testing: the bearing is strictly tested before leaving the factory to ensure the quality of every bearing we leave the factory. 3: complete models: bearing all types of complete, adequate stock, detailed customer service one-stop bearing procurement. Application: The products can be used for transmission, instrumentation, motor, household appliances, internal combustion engine, transportation vehicles, agricultural machinery, construction machinery, construction machinery, roller roller shoes, yo-yo and other machines.

Sealing cover material: galvanized iron cover/frosted iron cover/stainless steel cover/rubber cover. Ingenuity process Bainite quenching: the bainite quenching process is adopted, after quenching, the bearing molecules are closer and the service life is longer. CNC equipment automatic processing: the use of automatic CNC equipment processing and manufacturing, reduce the error and uncertainty of manual assembly. 1: smooth surface: bearing surface is smooth without burrs, smooth and convenient installation, surface polishing treatment. 2: No testing: the bearing is strictly tested before leaving the factory to ensure the quality of every bearing we leave the factory. 3: complete models: bearing all types of complete, adequate stock, detailed customer service one-stop bearing procurement. Application: The products can be used for transmission, instrumentation, motor, household appliances, internal combustion engine, transportation vehicles, agricultural machinery, construction machinery, construction machinery, roller roller shoes, yo-yo and other machines.